A trip to NMMC gold field

Mining is not an open field for everyone. That is, the work process is very complex and requires a lot of knowledge. Just as we do not know what lies beneath the earth, the hardships of the people working there are also unknown to us. Kun.uz journalist visited “Zarmitan” mine and got acquainted with the process of gold mining.

For information, “Navoi Mining and Metallurgical Combine” joint-stock company is among the ten largest gold-producing companies in the world. The combine is an industrial cluster in which production processes are fully implemented, from geological exploration, extraction and processing of mineral resources reserves to the production of finished products.

Kun.uz creative team got acquainted with the life of miners and aspects of the industry that we do not know about, using the example of a worker of the community-owned “Zarmitan” mine.

In August 2022, the depth of the “Skip” and “Klet” mobile mine in the “Zarmitan” industrial area reached 1,000 meters. This is a situation that has not yet been observed in the history of the industry in Uzbekistan.

Why are we focusing on the mine depth? Because various minerals are extracted from underground, first of all, getting to this layer is a laborious process. Conditions are created for working, breathing, and moving underground. In general, when you witness this situation for the first time, you cannot hide your surprise. However, this is not surprising for miners, who are going underground with you through a special device. For them, it is responsibility, care and hard work.

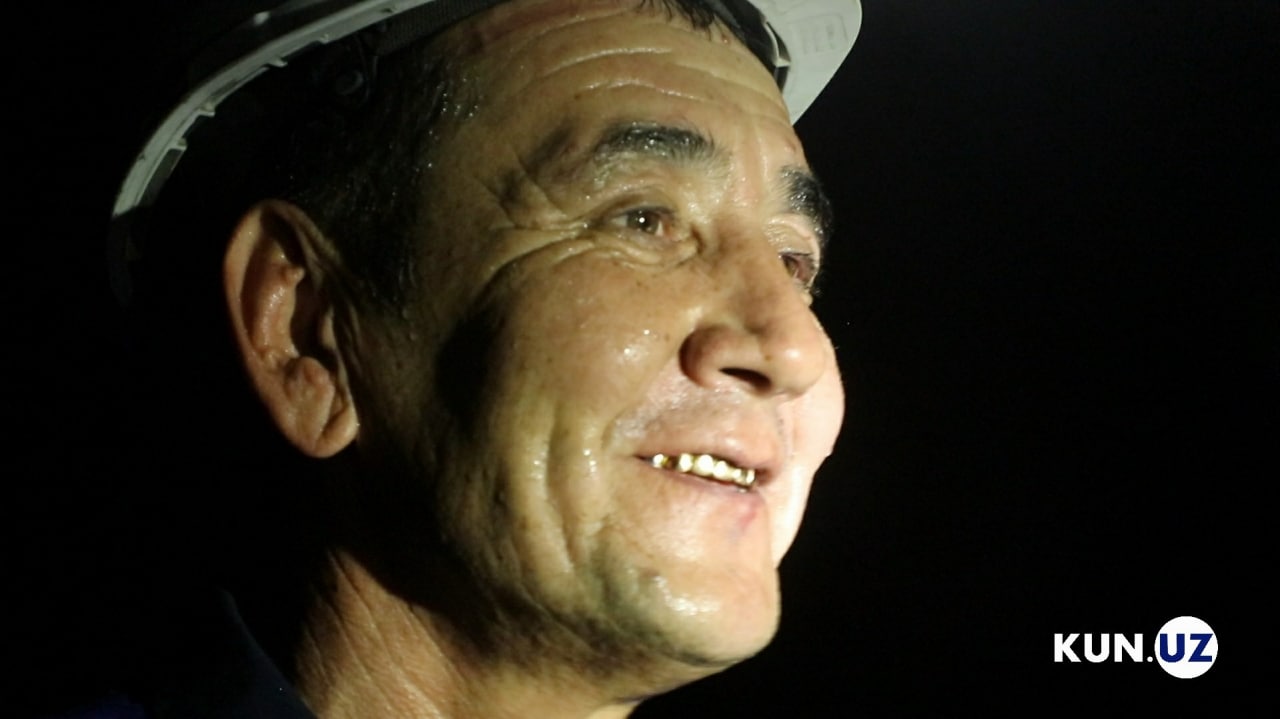

We went into the mine with Shavkat Tursunov, who works as a miner at the “Zarmitan” mine. He worked in the field for more than thirty years. Probably because we were going underground for the first time, the movement was very difficult. Your path to underground is not always smooth and bright. Sometimes there is water and mud under your feet, you need to be agile and alert to move. For miners like Shavkat bro, this is a daily routine.

By the way, Shavkat Tursunov also received three badges awarded to NMMC field workers. Not everyone in the industry can reach this level. He has been awarded the order of “Dustlik”. However, he is a miner. Every day he comes to work modestly, wears special clothes and goes underground. He does not boast of his awards and recognitions. The miner is always together with his apprentices and friends.

While we were filming his work process, he said that even the people at home do not know very well what task he is performing under what conditions.

“Our work is correct, complex and responsible. I spent my life in this field, educated my children, raised my daughters. The passion for my profession was inherited from my father. I grew up in these hills, among the mines. Frankly, even my wife did not have a complete idea of my work process until this moment. Here, you are filming, now the secrets must be revealed,” Shavkat Tursunov laughed.

Indeed, some cases cannot be written and described. You just have to see.

Keep up with the times

We also witnessed the process after the extraction of ores. Ores brought to the surface by workers are transported to the 4th hydrometallurgical plant not far from the “Zarmitan” mine. There, ore goes through several stages before turning into gold.

This plant also has a special laboratory, where experts with extensive experience determine the amount of valuable products in the ore.

The 4th hydrometallurgical plant was put into operation in 2010, and before that, the products mined from the “Zarmitan” mine were transported ninety kilometers at great cost and effort. The start-up of the plant was not only economical, but also created an additional five hundred jobs.

NMMC is among the world’s largest companies

The Navoi Mining and Metallurgical Combine differs from the world’s largest gold-producing companies: it is a huge industrial cluster connected to the technological chain from geological prospecting, mining, processing, and production of competitive and high-quality products.

The combine is increasing its production capacity every year. In the past two years, the 5th and 7th hydrometallurgical plants, based on modern technologies and fully meeting international standards, were put into operation. Also, the largest gold processing enterprise in the field of mining and metallurgy, the 2nd hydrometallurgical plant, which is the pride of our country, put into use the “B” corpus, which processes 12 million tons of ore per year.

This makes the NMMC stronger year by year among the world’s largest gold producing companies.

Related News

20:02 / 22.01.2026

Record gold sales lift Uzbekistan’s exports in 2025

13:55 / 23.12.2025

Uzbekistan halts gold exports for second consecutive month

17:12 / 17.09.2025

NMMC posts record revenue and profit in first half of 2025

20:54 / 28.07.2025